The step-by-step disassembly instructions presented here

apply to both the Stingray 1 and 2, and are a companion to our Maintenance, Cleaning

and Lubrication Guide. The only difference between the two Stingray

models is the barrel and top frame - the 'Ray 2 doesn't have a barrel shroud,

and thus has a different top frame. You can also refer to the Technical

Drawings for more information.

I highly recommend laying down an old towel to protect

your table, and to help keep round things from rolling away. Putting some

plastic (drop cloth, garbage bag, etc.) under the towel will protect the

work surface from getting oily. Use an old plastic margarine container,

egg carton, or similar container to put all the small parts in.

Tools Needed:

- 5/32" or 4mm allen wrench

- 3/16" pin punch, or #10 x 3" machine screw,

or 16 penney nail (with the tip ground flat)

- 1/8" pin punch, or #6 x 3" machine screw, or

8 penney nail (with the tip ground flat)

- 1/16" pin punch, or 1/16" rod or nail, or awl

- Small hammer

- Pliers

- Dental pick or small screwdriver

- Large screwdriver or old butter knife

Step 1: Begin by removing the plastic pins that hold in the aluminum barrel

and plastic shroud on the 'Ray 1, or the aluminum barrel only on the 'Ray

2. If the pins are tight, you can push them out from the other side with

a 5/32" allen wrench or 3/16" pin punch. You may need to tap lightly

with a hammer. Note: Some 'Rays have quick strip pins with rings

which pull out easily. Step 1: Begin by removing the plastic pins that hold in the aluminum barrel

and plastic shroud on the 'Ray 1, or the aluminum barrel only on the 'Ray

2. If the pins are tight, you can push them out from the other side with

a 5/32" allen wrench or 3/16" pin punch. You may need to tap lightly

with a hammer. Note: Some 'Rays have quick strip pins with rings

which pull out easily. |

The barrel and shroud

('Ray 1) or barrel ('Ray 2) should pull right out. It may be stuck with

dirt and/or dried paint goo, but a gentle side to side motion should work

it free. If only the shroud on the 'Ray 1 comes out, no problem. Pull the

shroud all the way off, then pull out the barrel. The barrel and shroud

('Ray 1) or barrel ('Ray 2) should pull right out. It may be stuck with

dirt and/or dried paint goo, but a gentle side to side motion should work

it free. If only the shroud on the 'Ray 1 comes out, no problem. Pull the

shroud all the way off, then pull out the barrel. |

Step 2: Remove the plastic pins that hold the grip frame to the top frame.

If they're tight, you can push them out from the other side with a 5/32"

allen wrench or 3/16" pin punch. You may need to tap lightly with a

hammer. Note: Some 'Rays have quick strip pins with rings which pull

out easily. After the pins are out, pull the grip frame and top frame apart. Step 2: Remove the plastic pins that hold the grip frame to the top frame.

If they're tight, you can push them out from the other side with a 5/32"

allen wrench or 3/16" pin punch. You may need to tap lightly with a

hammer. Note: Some 'Rays have quick strip pins with rings which pull

out easily. After the pins are out, pull the grip frame and top frame apart. |

This is what you should

have so far: This is what you should

have so far:

A - top frame; B - grip frame; C - retaining pins, long;

D - retaining pin, short; E - top frame pin; F - cocking screw; G - barrel

and shroud

Remember, if you have a 'Ray 2, you'll have just an aluminum

barrel, without the plastic shroud. |

|

Step 3: Remove the cocking screw

by turning it counter clockwise. (Righty tighty, lefty loosey!) If it's

stubborn, use a pair of pliers to loosen it. Wrap a rag around it first,

to protect it from the pliers. |

|

Step 4: From either side, using

your 3/16" pin punch (or #10 x 3" machine screw, or 16 penney

nail) and hammer, tap out the pin that holds the valve and tube assembly

in place. |

|

Step 5: Lay the top frame on the

table, and carefully slide out the valve and tube assembly. |

|

If the valve and tube assembly doesn't want to slide out,

the velocity screw may be holding it in. Using your 5/32" allen wrench,

screw the velocity screw in a few turns. |

To remove the detent

ball, you'll need to push out the roll pin which holds in the detent cap.

Using a 1/16" pin punch (or nail or awl), push the pin from one side

until you can pull it out with pliers. Put a finger over the cap before

fully removing the pin, or you'll lose parts. When the pin is out, very

carefully remove the cap, spring, and ball. To remove the detent

ball, you'll need to push out the roll pin which holds in the detent cap.

Using a 1/16" pin punch (or nail or awl), push the pin from one side

until you can pull it out with pliers. Put a finger over the cap before

fully removing the pin, or you'll lose parts. When the pin is out, very

carefully remove the cap, spring, and ball. |

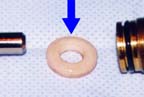

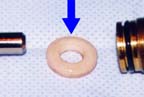

Here are the detent

parts: Here are the detent

parts:

A - detent ball (the stock ball is steel, not the acrylic

which is shown); B - detent spring; C - detent cap; D - detent pin |

When reassembling the

detent assembly, put the ball in first, then make sure the large end of

the spring goes against the ball. Caerfully hold the cap in place with a

finger, line up the holes, and push the pin through. You may have to work

with it a bit to get the pin to go all the way through. A little finesse

is called for here. When reassembling the

detent assembly, put the ball in first, then make sure the large end of

the spring goes against the ball. Caerfully hold the cap in place with a

finger, line up the holes, and push the pin through. You may have to work

with it a bit to get the pin to go all the way through. A little finesse

is called for here. |

|

Here is the valve and tube assembly. If any pins fell out

after you removed it, that's okay. Just don't loose them! |

|

Step 6: Remove the bolt by lifting

the transfer link out of the slot in the hammer, and sliding the bolt forward

off the bolt guide. |

|

Step 7: Remove the pins that hold

the donkey (CA adapter) in place. They may have already fallen out, or they

might fall out with a little gentle pushing and pulling on the donkey. If

not, tap them out with your 3/32" allen wrench or 1/8" pin punch. |

|

Pull the donkey out. The transfer tube will probably stay

in either the donkey or the valve - go ahead and pull it out. |

|

The donkey and one end of the transfer tube. The urethane

o-ring on the transfer tube can be clearly seen. |

|

The "business" end of the donkey. This is where

the CO2 tank screws in. You can see the brass colored depressor pin inside.

The depressor pin is what depresses the pin valve on the CO2 tank. |

|

Step 8: Remove the valve pin.

This pin may have already fallen out, or it might fall out with a little

gentle pushing and pulling on the valve. If not, tap it out with your 3/32"

allen wrench or 1/8" pin punch. |

Slide the valve out in the

direction of the arrow. If it's stuck, do NOT use pliers on the bolt guide.

Instead, push it out, after you've removed the hammer and spring (see below).

Or, using a wooden dowel or the handle of your scredriver, tap gently on

the back of the valve housing where it sticks through the top of the hammer

tube (opposite the velocity screw). Slide the valve out in the

direction of the arrow. If it's stuck, do NOT use pliers on the bolt guide.

Instead, push it out, after you've removed the hammer and spring (see below).

Or, using a wooden dowel or the handle of your scredriver, tap gently on

the back of the valve housing where it sticks through the top of the hammer

tube (opposite the velocity screw). |

Step

9: Push out the hammer, spring, and spring guide.

There may be a little resistance. If the valve is out, you can push the

parts out in the direction of the arrow, with a long screwdriver or piece

of dowel. Or, carefully push the spring and guide out by putting a screwdriver

tip in the slot in the hammer (bottom photo), and pushing them out. The

hammer should then come right out. Step

9: Push out the hammer, spring, and spring guide.

There may be a little resistance. If the valve is out, you can push the

parts out in the direction of the arrow, with a long screwdriver or piece

of dowel. Or, carefully push the spring and guide out by putting a screwdriver

tip in the slot in the hammer (bottom photo), and pushing them out. The

hammer should then come right out. |

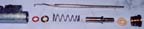

Here

are all the parts you've taken out of the valve tube assembly: Here

are all the parts you've taken out of the valve tube assembly:

A - valve assembly; B - transfer tube; C - donkey; D -

valve pin; E - valve tube; F - hammer; G - hammer spring; H - hammer bumper;

I - spring guide; J - bolt; K - bolt transfer link; L - donkey pins |

|

Step 10: Using your butter knife

or large screwdriver, remove the valve retainer by turning it counter clockwise.

Careful, it's spring loaded! |

|

After the valve seal retainer is loose, remove it slowly by

hand, being careful not to let the valve stem shoot out. |

|

The valve stem, seal, and spring should slide out easily. |

|

There are two parts down inside the valve housing, the washer

and o-ring. Carefully pull them out, using a dental pick, or small screwdriver. |

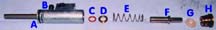

Here

are all the parts you've taken out of the valve assembly: Here

are all the parts you've taken out of the valve assembly:

A - valve body/bolt guide; B - velocity screw; C - urethane

o-ring; D - valve washer; E - valve spring; F - valve stem; G - valve seal;

H - valve seal retainer |

|

When reassembling, make sure the urethane o-ring is seated

in the groove down inside the valve housing. |

|

One side of the valve washer has a ridge on it. Make sure,

when reassembling, that the ridge side goes in first (towards the o-ring). |

|

When putting the valve seal back on the valve stem, make sure

the ridge on the seal faces the brass retainer. |

Obviously, reassembly is the reverse of disassembly. Just

follow the disassembly directions backwards, and you'll get it all back

together!

© Stingray Toters INternet Group

![]()

Step

9: Push out the hammer, spring, and spring guide.

There may be a little resistance. If the valve is out, you can push the

parts out in the direction of the arrow, with a long screwdriver or piece

of dowel. Or, carefully push the spring and guide out by putting a screwdriver

tip in the slot in the hammer (bottom photo), and pushing them out. The

hammer should then come right out.

Step

9: Push out the hammer, spring, and spring guide.

There may be a little resistance. If the valve is out, you can push the

parts out in the direction of the arrow, with a long screwdriver or piece

of dowel. Or, carefully push the spring and guide out by putting a screwdriver

tip in the slot in the hammer (bottom photo), and pushing them out. The

hammer should then come right out.